Lo sentimos, este artículo aún no está disponible en Español

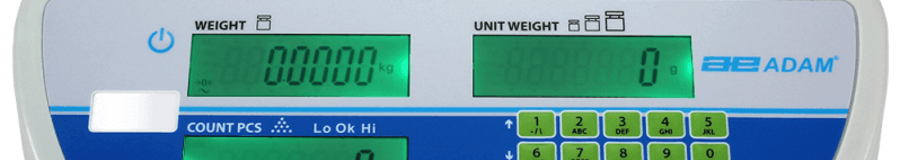

Counting scales are versatile weighing machines that can be used for counting and weighing objects simultaneously. Typical applications include checkweighing, for checking the weight of objects against a pre-set limit to performing accurate parts counting procedures to reduce manual counting. Counting scales come in a variety of sizes that can be used on a worktop bench or a floor respectively. Ideal for quality control centers, retail warehouses, production facilities and factory environments.

How do counting scales work?

As suggested, counting scales not only weigh, but also count the number of pieces in a lot. It does this by using a sample weight (either the first piece, or a weight you enter yourself through the keypad) and dividing the total weight by the weight of the sample.

Don’t forget that the scale counts by dividing the total weight by the sample weight. So you can’t put screws and bolts of different weights and get the right result. It only works with items that all have the same weight..png)

How are counting scales useful?

Counting scales are especially common in quality assurance departments and retail distribution warehouses for checking the number of pieces in a lot before being approved for dispatch. In addition, other manuafacturing based businesses such as printers, CD manufacturers, metal workers and plumbing supply companies often use counting scales. For example, plumbing supply companies can count the number of copper fittings they have left in a box, or update their hardware count without having to manually count each piece.They are also very useful for inventory taking, manufacturing and packaging. They allow you to not only check the number of pieces in a lot, but also to create lots that always have the right amount of material, and are perfect for counting a large amount of the same material.

Counting scales can also count coins or tokens when closing a store or totaling amounts and help reduce waste when filling packages and containers. The primary benefit of owning a counting scale is saving time and money.

What are some complimentary features/functions of a counting scale?

A full numeric keypad allows users to enter various sample weights. The size of the internal memory can also be useful, especially if you have to count a lot of different items; it allows you to recall sample weights with the keypad rather than constantly re-weighing the same items. Accumulation is another useful feature, especially for bench scales with a smaller capacity, or if you don’t feel like having your entire inventory on that scale. Accumulating the results allows you to store and box the items while maintaining your count. RS-232 and USB interfaces can connect the scale to a printer or a computer, allowing you to keep records, make an in-depth analysis of your inventory, or use a digital inventory tracking system.

Differences between internal resolution and displayed resolution

Internal resolution and displayed resolution are often used when describing counting scales, and despite similalrities they have very different meanings:

Resolution/ Displayed Resolution

This is the smallest change in the results detected in the measured sample by the weighing instrument. Usually, it’s called readability. To put it plainly, it’s the smallest number that the display of the scale can show.

For example, if you’re using a scale that only has a readability of 0.1g, it will not show you the weight of something that weighs 0.0052g. Display resolution is actually the ratio of capacity to readability.

Internal Resolution

This refers to how many pieces the scale’s full capacity can be divided into. It’s a ratio of the scale’s capacity to the weight of the lightest part it can count; basically, the scale or balance’s ability to convert the physical signals from the sample’s mass into a digital output.

The internal resolution is almost never the same as the display resolution, and most scales use a ratio of the two. If the ratio is 1:1, the readings are often unstable since the increments change so easily. Force motor balances, which tend to be scientific scales that require acute precision and are likely to be used in optimal conditions where the fluctuations in readings will be minimised, usually have a 10:1 ratio. Most scales that use a load cell have a ratio of 4:1 to improve the reading’s stability. As ever, there are other variables (such as temperature) that can affect the stability of reading.

Finding the best counting scale for your needs

As always, consider your needs and the applications you want your balance or scale to perform. For packaging or QC of small parts, a Latitude compact bench scale is an excellent option. If you’re in a warehouse or factory, a Cruiser CCT bench counting scale is probably your best bet. For industrial heavy duty counting, GFC floor scales are ideal with a solid stainless steel construction that is both robust and easy to wash down after use. A CBD counting scale can be connected to a seperate weighing platform to extend the capacity when needed (for end of year inventory, for example, or if you plan on expanding).

Don’t hesitate to contact us to if you have questions, and browse our website to see our selection of professional counting scales.